The house is turning white just in time for Christmas… No, it’s not snowing – this (yellowish) white Christmas is thanks to closed cell foam…

In other words our house is turning into a big styrofoam cup. 🙂 And actually it was sorta snowing in the house today – as they cleaned up this powdery foam fell down the staircase – much like snow…

The other day someone asked us what about the house was “green”. I always hesitate when people ask me that question – I don’t do things just because someone calls them “green”. For example NYC requires low VOC floor sealers which these days means water-based sealers. But traditionally oil-based sealers perform better than water-based ones. I’d have no problem shipping high VOC oil-based sealer in from Pennsylvania if it means our floors will be more durable. In that particular case we were convinced to go with a low VOC water-based sealer because the modern sealers have epoxy-like hardeners in them that make them perform better than the old oil-based sealers.

So I’m not green just to be green, but I am definitely green when it increases efficiency, durability, etc. (provided it doesn’t compromise on the end result). Insulation is a huge part how our house will be green since, more than anything else, it can reduce energy usage through lower heating and cooling bills.

I had done my research ahead of time and knew that closed cell foam just performs better than the other alternatives. For starters closed cell foam has a much higher R value per inch than fiberglass – 6 to 7, compared to 3.14. Thinner insulation = thinner walls = wider rooms. But beyond that we’ve been told that closed cell foam has a real world performance that’s twice as good as fiberglass insulation with similar R value. So an R20 closed cell foam wall will perform about the same as an R40 fiberglass wall. The reason for that is pretty simple… R value ratings do not take air movement into consideration. Closed cell foam gets into all the nooks and crannies and creates a seal – there’s no way for air to get around the insulation. In contrast air can travel pretty easily around fiberglass batts.

To illustrate that point I went with a friend a few months ago to see a place in Brooklyn that was under construction. They were insulating, but in the most haphazard way possible… There’s no way the wall below is going to perform very well – look at the huge gaps in some areas and how it’s squished the fiberglass is in other areas.

In contrast closed cell foam tends to be a little oversprayed – so if anything it will perform better than expected and since it creates a perfect seal all over the wall – there’s no problem with air passing through the wall.

So sealing the house up really tight should drastically reduce energy consumption. Over time that will save us money and pay for the increased cost of the closed cell foam.

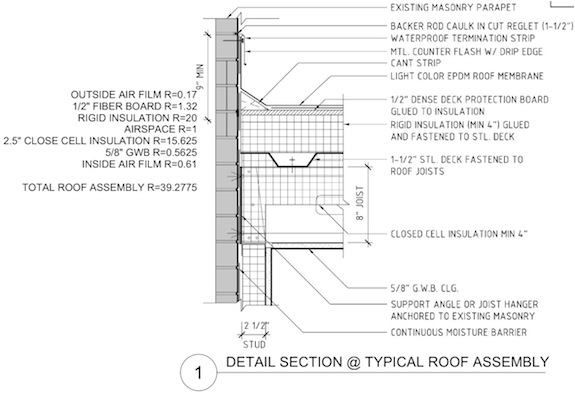

If your curious, here’s how the floors and walls are being done. NY State energy code requires R19+ walls and R39+ roofs (I think those numbers go up if the building is heated with electric). [And I should mention, if you’re landmarked or on the National Register you’re exempt from energy conservation rules. But seriously – if insulation will save you a substantial amount of money, why wouldn’t you want to insulate properly?]

That’s 2.5″ of closed cell foam, plus the R value of the brick, etc. gives us R20 walls. Actually, the R value of the brand we’re using is slightly higher than the architect expected, so we’ll have R21.5 walls.

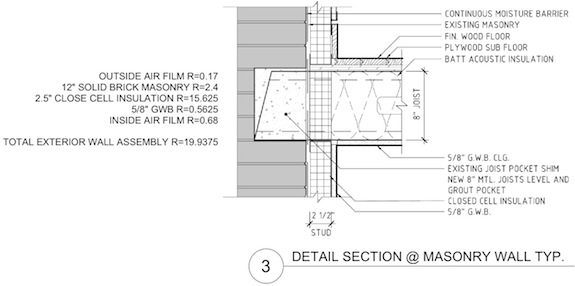

That’s 4″ of rigid foam above the roof deck (rigid foam is similar to closed cell – except it’s not sprayed on and hence isn’t as air tight), plus 4″ of closed cell foam in the roof joists.

If you look closely at the image above you’ll see an inconsistency – the calculations say 2.5″ of foam, the detail drawing says 4″. I didn’t catch that until earlier today when they’d already started insulating. On top of that the insulation guy put 5.5″ of closed cell (R38) in his estimate, so our roof will be more like R61.5 with about R41.5 in the bulkhead. That amount of roof insulation is actually almost absurd – R60 is what “zero energy” homes have. With 3″ of closed cell foam you get 97% of its potential efficiency. So with 9.5″ (including the rigid insulation), most of our roof has got to be pretty close to 100% efficient.

The other thing closed cell foam does is reinforce the structure of the house. Because it becomes rather hard when it drys and because it fills every nook and cranny it actually becomes somewhat structural – all without adding much weight. We were told it can make a typical wood frame house 40 times stronger than normal which makes it popular in hurricane zones. We’ve got brick walls, so that’s not a big factor – but it can’t hurt.

The one downside to closed cell foam (other than cost) is that you have everything in your walls completed perfectly before you spray on the foam. Going back and fixing something you didn’t quite get right is incredibly difficult.

One thing we should mention is closed cell foam on brick walls. We were told by one insulation sub-contractor that old brick would suck up the equivalent of 1.5 inches of foam. But it turns out that was just wrong. The closed cell foam expert that we’re using says the foam is applied at 150 psi and starts drying and hardening almost immediately. It doesn’t really have time to get sucked into the brick.