The other day someone asked me what I would do differently if I had it to do over again. I gave a few examples (the biggest being to get water and electricity up and running before you start construction), but I’d add a better soundproofing strategy to that list. In our case it’s mostly an issue between the two units, though we are a bit disappointed in how you can hear footsteps on the floor above you in our unit. We’re scrambling to try to come up with a better solution for between the two units. In hindsight it’s something we should have taken more time to consider during the planning phase.

The main issue is that our living room is on top of our tenant’s bedroom. If we don’t take soundproofing seriously we’re going to have a very unhappy tenant every time we have people over for dinner or a party.

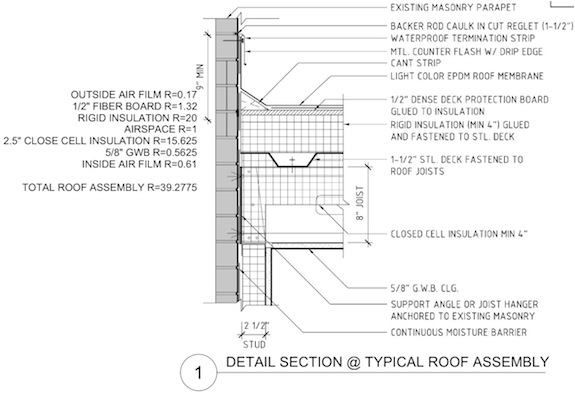

The first thing we did was an $800 change order to upgrade from fiberglass batt soundproofing to open cell foam soundproofing between the two units. I know there’s some debate about which is better. The fiberglass folks say fiberglass is better, the foam folks say foam is better. Fiberglass apparently has a better (or similar) STC rating (Sound Transmission Control), but open cell foam is supposed to be good at blocking mid-range frequencies like voices. But, that said, we’ve noticed you can still hear voices through the open cell foam – which worries us. Mind you, the ceiling/floor isn’t finished – it’s just a plywood floor subfloor plus the 5+ inches of foam at this point, but we figure we need to do more.

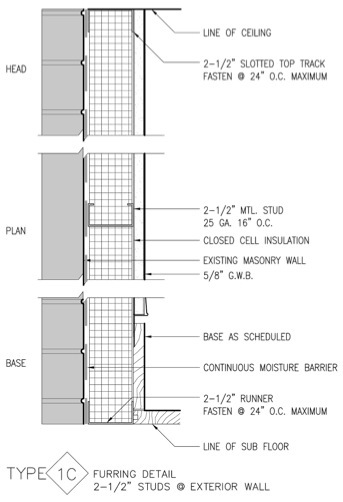

The next big thing we’re doing is metal channels that hang perpendicular to the floor joists. Between the joists and the metal channel is sound proof caulking/foam. Here’s a picture of the channels…

You can also see all the open cell foam in the picture above.

The channels screw into the joists on one side and then the sheetrock screws into the channels. Because the channels are just screwed on one side they bounce a little – that bounce is a good thing when it comes to sound.

I’m pretty sure we need to put two layers of 5/8″ drywall on the ceiling since the ceiling has a 1 hour fire rating. So there will be more sound proofing foam between the layers of sheetrock and all the mass of the drywall will really help cut the sound as well.

With any luck our tenant will sleep soundly – even when we’ve got guests over…

Update:

Two layers of 5/8″ drywall have gone in on the ceiling and things are MUCH quieter now. They still need to tape and do the wood floor, but so far voices and footsteps are significantly muffled – though still sorta audible. And the resilient channel does indeed help things. When I walk across the floor with heavy boots Dan could tell when I was over the section with channel.

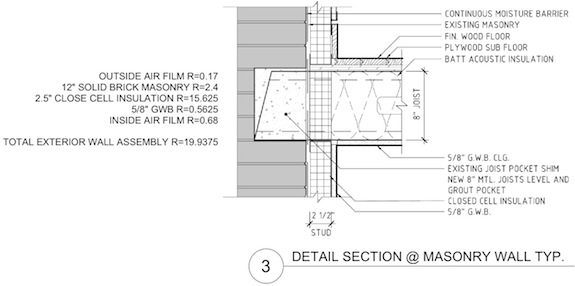

Notice his note for a “continuous moisture barrier”. Basically “moisture barrier” is a fancy term for a sheet of plastic – there’s not much high tech about it.

Notice his note for a “continuous moisture barrier”. Basically “moisture barrier” is a fancy term for a sheet of plastic – there’s not much high tech about it.