[This blog post is not “legal advice” – readers should consult a lawyer for all legal matters. Instead, this blog posts reflects what Dan and I, as homeowners, have learned by going through the process of having liens put on our homes and being sued by contractors.]

Our townhouse got its first (and hopefully only) mechanics lien last month. Our contractor decided to not have his stair subcontractor (and “friend” – Adam Wedrychoski of ABC Stairs Builders Corp – aka “Traditional Stairs Corp”) complete the stairs because he was too expensive and the budgets had gotten tight. Adam got disgruntled and is now going after us for $9,600.

We’ve gone through this before when the contractor for our apartment remodel (Bill Angelov of ABS Construction) went after us a few years ago (a blog post is pending on that one). We were amused that Adam Wedrychoski / ABC Stairs Builders even used the same lien service Bill Angelov / ABS Construction had used – Speedy Lien. Unfortunately the New York court system, and companies like Speedy Lien, make it so disgruntled workmen/contractors/subcontractors can put liens on your property without any proof that they have a legitimate claim.

This isn’t a horrible thing… Liens are good in that they alert purchasers of a property that there may be claims on a property. They also insure that people who add value to a property are compensated when the owner sells the property. But ultimately, they’re just a first step and the workman / contractor / sub-contractor needs to prove their claim in court.

In this case Adam Wedrychoski / Traditional Stairs Corp has no basis for putting a lien on our property. He has no contract with us, nor was there an implied contract with us (e.g. we never paid him directly). He was a subcontractor working for our contractor. If he had talked to a lawyer, he would know that all he is legally entitled to do is sue our contractor. We do have a contract with our contractor, but every time he gets a payment from us he signs a lien waiver stating that all of his subcontractors have been fully paid.

The amount of the lien doesn’t even make sense – which seems typical of liens by Speedy Lien… He took the total amount he would have been paid if he had completed the job, subtracted what he had been paid, and then put a lien on us for the difference. So he’s essentially asking for money for work he didn’t do. Thankfully our court system doesn’t think the same way Adam does.

When we contacted Wells Fargo (the lending bank for our mortgage), what they said worried us – they stop all payments of any kind if there is a lien in place. They wanted us to “settle” with Adam Wedrychoski / ABC Stairs Builders Corp and they erroneously told us that they don’t accept bonds.

Thing is, bonding the lien is the correct way to deal with the situation. It’s actually sort of cool how bonds work… You contact a surety agent (ours is Elmer Hyde Agency), and give them 110% of the lien amount plus a few hundred in fees. They bond the lien, and you file that paperwork along with some other affidavits with a clerk at the court building (harder than it sounds) and the lien is discharged. Once the lien is discharged, it no longer exists. That means your title is clean and your bank will be happy.

If the workman/contractor/subcontractor sues you and the court finds in his/her favor, the bond is used to pay the judgement and you get whatever is left over. Liens are for one year and they can be renewed once – so they can only exist for two years total. If the workman/contractor/subcontractor doesn’t sue you during that time, then you get the bond amount back with interest. However, the workman/contractor/subcontractor can sue you for up to 6 years (in NY), but after the bond expires, s/he just has to hope that you can still pay.

While it may seem odd to welcome a lawsuit, we’ve been through the process before and our attitude is “bring it on”. Adam Wedrychoski / Traditional Stairs Corp is in an impossibly difficult position. Because he is a corporation he is not allowed to show up in court without a lawyer. Because lawyers typically take a percentage of the settlement, they won’t take the case on unless they think they’ll get paid. They would typically get 1/3rd – and 1/3rd of $9,600 ($3,200) isn’t enough for them to bother with the case. And that assumes they’ll get the full amount – which they know they won’t. That means the only way Adam Wedrychoski / ABC Stairs Builders Corp can get a lawyer, and hence the only way he can sue us, is if he pays his lawyer hourly. Bottom line – he will lose a substantial amount of money if he tries to sue us.

While Adam Wedrychoski / Traditional Stairs Corp has to have a lawyer, we’re individuals, so we can represent ourselves (this is one of the advantages of not putting our building in an LLC). The courts are very lenient with pro se defendants – there are actually judges that only hear cases with pro se defendants. Plus pro se defendants can go in and get free help with filing paperwork, etc. So while it can be time consuming to show up at all the hearings, it doesn’t actually cost us much of anything. Meanwhile he’s paying his lawyer hourly, so if you do the math its in our best interest to drag things out and have as many hearings and motions as possible. 😉

If Adam Wedrychoski / ABC Stairs Builders Corp sues us, the first thing we’ll do is a show cause motion – making him prove that he has standing to sue us. He will fail because he can’t produce a contract with us. No contract = no enforceable terms.

Incidentally, people often think that the loser pays the winners attorney fees, but that’s not the case at all (at least not in New York). That only happens if you have a written contract saying that’s what you agreed to – and of course Adam Wedrychoski / Traditional Stairs / ABC Stairs Builders has no contract with us. That is why we’re confident Adam will lose money if he pursues this, but it gets better…

If he does survive the show cause motion, our next step will be a counter suit. The stairs in the rental are not according to plan – they’re too narrow (the stringers are not flush with the sheetrock), and they’re made of red oak, not white oak. On top of that, the stairs in our unit are not square and the contractor had to correct a number of things that Adam / Traditional Stairs didn’t quite get right. In fact things are so bad our architect suggested either we or our contractor sue him for everything he’s received – about $20,000. At one point we detailed a whole list of things that we wanted him to fix and he never came back to fix them – instead the contractor had to take care of it.

In case you’re wondering, Adam’s / ABC Stairs Builders Corp’s lien is an attempt to get paid for having to fabricate and install the flight of stairs from the parlor to the 2nd floor three times. When this was all going down we insisted that he do shop drawings, he refused and promised to fix any problems that resulted from not having shop drawings. I even mentioned that understanding up in a blog post. He even started before our architect gave him the green light. If he had just waited for approval to start we could have avoided at least one of those fabrication/installs. Plus, we’ll have our contractor, and our architects testifying that that we did in fact insist on shop drawings and that he agreed to fix anything that was a problem.

There is simply no way he can win his case, but I’m pretty sure we can win a fair amount of money on our counter suit. That means if he sues us, between lawyers fees and our counter suit, it will be a lose-lose proposition for him. Which is why our attitude is “bring it on”…

Thing is, all of this affects our contractor more than it affect us. The contractor is liable for the actions of his sub-contractors – including any liens they put on us. So the bond money is coming out of what he would have gotten at the end of the project. All Adam has accomplished with the lien is hurting someone who used to consider him a friend.

The bottom line is, be careful in dealing with contractors and subcontractors. Lien waivers and receipts of “final payment” are always a good idea. And summarize important conversations in writing/email after they occur so there’s documentation. Then when you get a mechanics lien, just bond it and put the ball back in the workman/contractor/subcontractor’s court.

Honestly, I think a lot of (sub)contractors don’t understand the process and have never heard of a bond. They just hear that liens scare some homeowners into settling. They don’t understand that they may actually have to sue the homeowner to get any money. They definitely don’t seem to understand that filing a lien starts a process which could result in them losing a considerable amount of money…

As a homeowner just realize you don’t have to settle with someone who is putting a lien on your property to harass and intimidate you – you can bond the lien and regain the upper hand in the situation.

It’s really not all that spooky with all the height and the open risers – unless you’re silly enough to actually look over the railing and down the center core… Here is the view looking up…

It’s really not all that spooky with all the height and the open risers – unless you’re silly enough to actually look over the railing and down the center core… Here is the view looking up… There had been some debate between the stair guy and our architect. Our architect insisted on a pretty gentle 7″ rise from step to step. The stair guy was used to doing 7.5 to 8″ rise. Logistically we had to do 7.5″ rise on the top and bottom flights, but the two in between are 7″ rise. I gotta say you don’t get all that winded walking up the stairs when the slope is nice and gentle – our architect really knew what he was doing…

There had been some debate between the stair guy and our architect. Our architect insisted on a pretty gentle 7″ rise from step to step. The stair guy was used to doing 7.5 to 8″ rise. Logistically we had to do 7.5″ rise on the top and bottom flights, but the two in between are 7″ rise. I gotta say you don’t get all that winded walking up the stairs when the slope is nice and gentle – our architect really knew what he was doing…

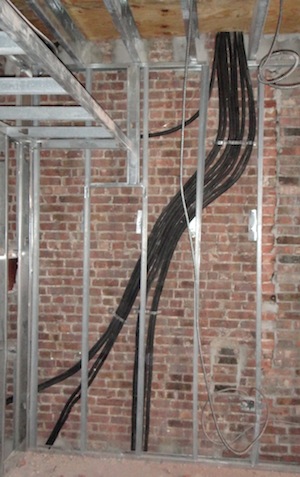

A/C refrigerant lines going in

A/C refrigerant lines going in Sprinkler risers going in

Sprinkler risers going in General plumbing being completed

General plumbing being completed Street torn up, but water main connection delayed

Street torn up, but water main connection delayed

Stoop restoration begun

Stoop restoration begun The narrow portion is new, the wider area is the original portion… Looks pretty good…

The narrow portion is new, the wider area is the original portion… Looks pretty good… You can’t really tell from the picture, but it feels like a bit of a monster in the space. One thing we like is that it has glass doors (required by code), but they can be retracted into the sides so it sorta looks like it doesn’t have glass doors.

You can’t really tell from the picture, but it feels like a bit of a monster in the space. One thing we like is that it has glass doors (required by code), but they can be retracted into the sides so it sorta looks like it doesn’t have glass doors. We figured the bulkhead would catch a lot of light and we wanted to make the most of it. But back then we thought the stairs up to the roof were going to be L shaped – we didn’t realize they would need to be U shaped. The extra run blocks a lot of light from getting down into the stairwell – unfortunate, but it is what is is.

We figured the bulkhead would catch a lot of light and we wanted to make the most of it. But back then we thought the stairs up to the roof were going to be L shaped – we didn’t realize they would need to be U shaped. The extra run blocks a lot of light from getting down into the stairwell – unfortunate, but it is what is is.