Today was not a good day. The ConEd guy came by and said it could be as much as 3 more months to get gas and electric service. We’ve already waited 5 full months – so that means 8 months to get utility service. That’s absurd.

The first five months was because ConEd refused to install their part until DEP had installed the new water main connection. Word to the wise – just flat out lie to ConEd and tell them you’re using the existing water main connection. The water main sub contractor will be under the control of your contractor – just get them to dig carefully. Also, a good idea is to put the new gas and electrical connections as far away from the water main connection as possible – it will minimize the chance that ConEd’s stuff will be disturbed.

But the rationale behind the additional 3 month wait is just retarded. Apparently ConEd only has one contractor working for them who’s got clearance to dig up streets in New York. There’s another contractor lined up but someone is dragging their feet signing the paperwork to get that contractor going. Meanwhile the first contractor has a backlog of 70 to 80 jobs, hence the 3 month wait.

But it gets worse… ConEd’s budget for installing new electrical/gas service is nearly exhausted. There’s no money at ConEd to pay their contractor to do the installations. What properly run business doesn’t have the money to start up new accounts? That just boggles my mind. They have to spend the money sooner or later and the sooner they do the installation the sooner they make money off us.

Needless to say, I blew up. 8 months is insane. The ConEd guy said he couldn’t start our 3 month wait because the electrical / plumber hadn’t put in the new sleeves (holes in the wall). So I was all over the electrician asking why they weren’t done yet. He said they weren’t done because he said ConEd said they wanted to wait for the water connection to be done. So I pushed further – why not just put them in anywhere (they could always be redone)? Then the electrician and the ConEd guy both tried to say they had to wait to see where the water connection came through the wall. I wasn’t having that excuse – the water connection came through EXACTLY where it had been before. Nothing changed.

Then I was all over the ConEd guy – if he knew it was a 3 month process why didn’t he say something to that effect earlier? Why not get us into the queue months ago? Why do we have to wait 5 months to start on a 3 month wait? If he had put us into the queue at 2 months we would be at the top of the queue now and everything would be fine. After waiting for 5 months we shouldn’t be told we have to go to the back of the queue.

When it was clear the ConEd guy was at fault, he said he needed to go to another appointment and he just turned and left. Nice. He causes us major problems and can’t even say ‘sorry’.

I should stop and say that as much as I rag on the bureaucracy at City agencies, our experience with DEP to get the new water connection was nearly flawless by comparison. Despite a hurricane doing a direct hit on the City, DEP managed to get us a water connection two weeks and two days after we got final signoff from DOB. Kudos to DEP!

The only silver lining to all of this is that the additional 3 month wait won’t hold anything else up. The electrical and gas inspections can be done without electrical or gas service. So we can close up the walls, etc. Still, it’s a bit insane that we won’t get electrical and gas service until right before we move into the building. Pretty much the entire job will be done off generators. Hopefully there won’t be freezing weather before we get gas and electric, since we’ll need those for heat to stop the pipes from freezing.

So there is something worse than the NYC Department of Buildings… ConEd…

Update #1 (that night): I’ve filed a complaint with the New York State Public Service Commission Office of Consumer Services. They have a handy online form you can use to make complaints against utility companies. We’ll see if it helps.

Update #2 (the next morning): Dan called the guy’s boss and left a message and then the boss called back a half hour or so later and said he had talked to the guy several times about us this morning. I think after I blew up yesterday the guy realized he had to do something. They’re now on top of things and are going to make sure there are no delays. The boss reiterated what I had been told that 3 months is a worst case scenario, but he didn’t say what the average wait time is. If it’s 2+ months then it’s still the same problem. We don’t know whether he’s aware yet of my complaint to the public service commission. But our strategy at this point is to be a very squeaky wheel that can’t be ignored.

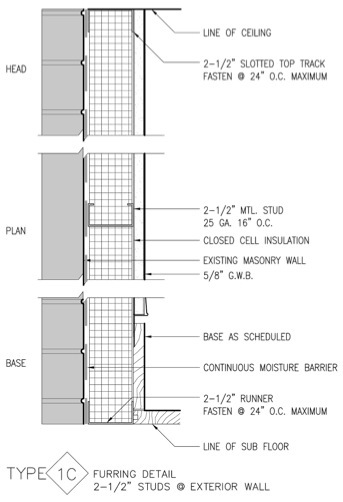

Notice his note for a “continuous moisture barrier”. Basically “moisture barrier” is a fancy term for a sheet of plastic – there’s not much high tech about it.

Notice his note for a “continuous moisture barrier”. Basically “moisture barrier” is a fancy term for a sheet of plastic – there’s not much high tech about it.

Compare that to what it looked like when we bought the place – much smaller and just a galvanized pipe (I assume now they’re using black pipe)…

Compare that to what it looked like when we bought the place – much smaller and just a galvanized pipe (I assume now they’re using black pipe)…

It’s really not all that spooky with all the height and the open risers – unless you’re silly enough to actually look over the railing and down the center core… Here is the view looking up…

It’s really not all that spooky with all the height and the open risers – unless you’re silly enough to actually look over the railing and down the center core… Here is the view looking up… There had been some debate between the stair guy and our architect. Our architect insisted on a pretty gentle 7″ rise from step to step. The stair guy was used to doing 7.5 to 8″ rise. Logistically we had to do 7.5″ rise on the top and bottom flights, but the two in between are 7″ rise. I gotta say you don’t get all that winded walking up the stairs when the slope is nice and gentle – our architect really knew what he was doing…

There had been some debate between the stair guy and our architect. Our architect insisted on a pretty gentle 7″ rise from step to step. The stair guy was used to doing 7.5 to 8″ rise. Logistically we had to do 7.5″ rise on the top and bottom flights, but the two in between are 7″ rise. I gotta say you don’t get all that winded walking up the stairs when the slope is nice and gentle – our architect really knew what he was doing…

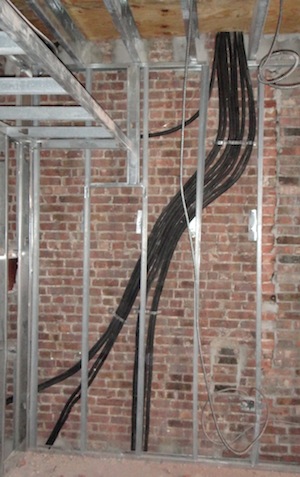

A/C refrigerant lines going in

A/C refrigerant lines going in Sprinkler risers going in

Sprinkler risers going in General plumbing being completed

General plumbing being completed Street torn up, but water main connection delayed

Street torn up, but water main connection delayed

Stoop restoration begun

Stoop restoration begun The narrow portion is new, the wider area is the original portion… Looks pretty good…

The narrow portion is new, the wider area is the original portion… Looks pretty good… You can’t really tell from the picture, but it feels like a bit of a monster in the space. One thing we like is that it has glass doors (required by code), but they can be retracted into the sides so it sorta looks like it doesn’t have glass doors.

You can’t really tell from the picture, but it feels like a bit of a monster in the space. One thing we like is that it has glass doors (required by code), but they can be retracted into the sides so it sorta looks like it doesn’t have glass doors. We figured the bulkhead would catch a lot of light and we wanted to make the most of it. But back then we thought the stairs up to the roof were going to be L shaped – we didn’t realize they would need to be U shaped. The extra run blocks a lot of light from getting down into the stairwell – unfortunate, but it is what is is.

We figured the bulkhead would catch a lot of light and we wanted to make the most of it. But back then we thought the stairs up to the roof were going to be L shaped – we didn’t realize they would need to be U shaped. The extra run blocks a lot of light from getting down into the stairwell – unfortunate, but it is what is is.